-

Posts

7,177 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Store

Everything posted by AlanM

-

Do you put the silicone on the edges and also on the glass with some tape to confine it? Or just blob it between two straps of tape and smoosh the baffles into it?

-

Right. Supposedly the acrylic eventually swells. That might have eventually made it hold, but it failed too soon, heh. Maybe if I had measured 1/8 instead of 1/4 smaller to do the cut... So now i have these acrylic sheets with 1/8 on the sides. I will try to use rtv100 to hold them in. Think that will grab em and hold?

-

So the epdm foam thing doesnt work. It holds for a while, but starts slipping and then it seems to be game over. I had 12 inches on one side and 11 inches on the other. You wouldnt think an inch would push that hard but it slipped and just failed totally. Also, the adhesive is extremely difficult to get off the acrylic edge. Maybe it would have held if i had mde the bffles larger so they would be tighter, but i just followed the instructions...

-

I think very few people should take Paul's implied advice about not testing and not worrying about water quality, etc. The fact is that Paul is very experienced with a very established tank and a lot of inertia if things start to go wrong and he can get away with not testing every little thing. Me with my first saltwater tank, fresh sand, dead rock that I'm going to try to make alive, etc., I have no choice but to try to control my parameters and test and hope they're good for at least the first 5-10 years, and then I can start to coast. 8)

-

You can get meters at Lowes or HD or radio shack, but if you put it on the Apex without blowing into anything it should say "Switch 1: Closed" down at the bottom of the dashboard that comes up when you log in over the web. The rest should say Open. Seem like if you don't have a multimeter already, the Apex would function as a good one now that you know it's going to switch 1.

-

Nope. looks like a brown wire to me, doesn't it to you? The red one is the little stub that they cut out. I can see it in your picture. The labels on the diagram I posted above were for some other device. I posted that diagram to show you which pins the wires go to, not for the labels. Assuming the pressure switch works, and you should be able to hear it click when you blow lightly in the tube, you should be able to stick a meter between the two terminals that the brown (not red) and the black wire connect to and see that it is continuous when you're not blowing and opens up when you do.

-

Ok, so the opamp should still get power from the header pins 2 and 4, and that's what I'm testing right?

-

I do have an old Fluke Scopemeter that I can check between pins 3 and 4 to see what is coming out. I'm nervous about shorting pins 3 and 4 since the Apex input is on those. Dave S said the following earlier in this thread:

-

I ordered the weatherstripping from McMaster-Carr that they cite in the article and just installed some baffles. No water in it yet. Will do that tonight or tomorrow night and let folks know how it holds and if it leaks.

-

Yeah, if you open the box you can see if it's brown wire and black wire.

-

Haha, nope. I'm a dummy. I just don't mind clipping wires that I'm pretty sure I can get back together. Remember I already let the smoke out of one of my dimmer boards on the d120 with a battery, so now I have to get it working. 8)

-

It's not old telephone cord. It's cat5, and I say what they are in my post, blue/white is 0-10v from Apex, green is negative from Apex (ground). I also describe what those black and red ones are in my post. I also describe how I pulled the two resistors with no change. 0.25Amps is on the LED light string, not on the Apex or the dimmer lines. 250mA is the lowest current it goes to with the opamp between the Apex and the d120. When hooked up directly up to the Apex it goes to 170mA on the LEDs. I don't know if pin6 follows pin3. I'll check. What do I reference them both to to check? Pin 4?

-

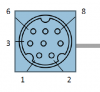

It should definitely be switch 1. It's normally closed when the water level is low and opens when the water level rises in the sensor tube (or if you blow on it). Continuing my sacrificing my stuff in the name of science, I clipped the mini-din9 connector off the locker I bought. I want to put it into the breakout box instead of directly into the Apex so I can put in some float switches and water sensors too. The Avast locker sensor uses the brown wire and black wire of a mini-din9 which are hooked to the connector as in the image below. The comprehensive guide to Apex numbers the pins like the image below with 1 on the bottom left and working your way up to 6 on the top left. Number 8 on the top right is the common for all of them (black wire). 7 is unused. So if you put an ohmmeter between pins 1 and 8 on your connector you should see continuity that goes away when you blow on the sensor. If it doesn't, maybe yours is broken.

-

Tom, With the op-amp hooked up as you describe above the minimum current is 0.25A on the LED. It does ramp up to 0.58A similar to the direct hookup. With it hooked up directly to the Apex the minimum is 0.17A. I tried it with the 100k and 20k resistors and without them, and there was no difference either way. Here is a pic attached of how I hooked it up. The red wire you see coming from pin 7 on the 741 goes to pin 2 on the d120 header (which is shorted to pin 1 to get the lights to turn on). The red wire from pin 6 of the 741 goes to pin 3 on the d120 header and the black wire from pin 4 goes to pin 4 on the d120 header. The blue/white is 10V from apex, the green is ground from apex. Do you see something wrong?

-

I only know how to do it with the web interface, which I assume the Jr has. Just click on Outlets under configuration and pick the one you want to rename from the dropbox one at a time and start renaming them in the text box and hitting save. Then on the front dashboard that loads as the default turn them on/off as your heart desires. They're probably named things like "Skimmer, pump, powerhead" and stuff right now.

-

You could at least rename the outlets on your powerbar with what is plugged into them. Oh, and the default is that theyre set to auto with some default program that turns them on and off all the time. You should set them to off or on if you want to use them as a powerstrip.

-

I will post pictures when I get back from my in laws house tomorrow. But some of the other pics on the thread here may help. There are pics of the dimmer boards at least.

-

Especially since it is in the wall an external overflow seems perfect. Could also try one of these type. http://www.reefcentral.com/forums/showthread.php?t=2160311

-

Cut a slot in the top of the back and glue a box on the outside of the back with holes drilled on the bottom for drains. External overflow box. I guess youd plug the existing internal holes on the bottom or use em for a closed loop.

-

will do. Good idea.

-

Haha, right, but I hope this wouldn't fry your router with only 2.33mA.

-

It works!!!!1!!1!! The easiest way possible, like Tom thought it would. Video below. I just decided to risk sacrificing my VDM in the name of scientific progress. I did what Tom suggested to just try hooking the darn thing up to the VarSpd ports on the Apex and drive them. It works just fine. In the video you can see my little multimeter measuring current on the LED string. I flipped the outlet that activated a ramp profile to go to 0 to 100 in 1 minute. Max current is 580mA (I hooked it up backwards in the video), which is right. The min current is 170mA, so it doesn't dim as low as it does with the pot, probably because the Apex, has a little bit of internal resistance even when you're not supplying a voltage on the VarSpd ports. I have the d120 plugged into outlet 1 of my EB8 and called that one d120s and turned it off to turn it off all the way. So it seems all you need to do to control it is to get a little 4 pin header, unplug the pot board, short out pins 1-2 to power it on, then hook up pins 3 and 4 to the + and - wires coming out of the Apex VarSpd port. Or just snip off the connector and solder the wires together. Ooh, or cut a little square in the metal panel on the top and put a keystone RJ45 jack, then you could just use a Cat5 patch cable to go between the Apex and the d120.

-

Well, we had a drawer of 741 chips, and lots of resistors, so I will try that first and then do apex directly.

-

Will try it this evening.

-

I now get why it is called a unity gain amplifier. It isnt giving more current. It is just isolating the Apex side from the driver sense circuit side. I will risk the VDM by just hooking it up across the snipped wires which used to go to pins 3 and 4 to see what happens since I really did only see a couple milliamp through there. In that case I dont have to set it to max bright at all because the dimmer board is not even in the picture. I dont think pin 1 and 2 are supplying current to the auxiliary board at all, by the way. When I look at the traces those two pins go right in and out. Unless it goes back in to the driver and out to the dimmer board.

.thumb.png.40db71e145957fbc22a7d873e5f3065b.png)