-

Posts

10,430 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Store

Posts posted by jason the filter freak

-

-

I dont have room for a brute trashcan. Something is leaching Ammonia in my RO/DI storage setup and I suspect it's my storage containers. I need suggestions for pins totes in the 15-25 gallon volume range that are safe for RO/DI storage.

-

Update: Tank is back to 1.025, anemone has reattached its foot. Guts are still part way out but not as dramatically.

-

3 ATO and back up failed in the on position and I ended up with a specific gravity swing from 1.025 to 1.020. The anemone has started to spew its guts through its mouth and the foot is semi detached.

I'm working on bringing the salinity back up. But at this point would you pull the anemone so it doesnt nuke the tank (6" Heteractis, in 90 gallon water volume) or give it the day to try and recover. No SPS or LPS in the tank just other anemones, fish, and zoa/paly.

-

Yes but it's much harder when you're oconus.

-

As long as I've been in the hobby I've never had a sand sifting goby but I've always been enamored with them. I was thinking of taking a shot with my current set up. I'm going to have a sand anemone which for all intents and purposes is "the same" as a Sense. I know that people complain they will bury corals resting on the sand bed. However are they likely to bury an anemone?

-

7 hours ago, maevepotter said:

Ooooooooooooooo

Sent from my Pixel 3 XL using Tapatalk

Ahhhh

-

Hope things got better for you. How are you making out on the skimmer?

-

Welcome to WAMAS. I started here back when I was a young whipper snapper too. I dont even live in the DMV area anymore but keep on with these guys because they are the literal best source of info and a patient ear of any group or forum out there.

-

In case anyone was on the fence Maxspect gyres are clossal pieces of ****. Theyre (xf330) louder at 50% than my MP10QDs were at 100%, the magnets are absolutely trash, the in-tank profile is enormous, the programming isnt even slightly intuitive, their phone line for "customer service" is quite literally fake, and theyre email support is a joke.

/rant

-

@Still_human Hows this project coming?

-

Reefbot

-

For super bad build up on smaller parts (needle wheel, volute, Venturi etc.) I'll do 100% vinegar, general soaking for poor maintenance (my own fault or someone else's) a 1:3 or 1:4 ratio, general bi-yearly service 1:4 or 1:5 ratio. There's really no science to back this up just more of "it worked in the past so why not". You're really not going to hurt anything aside from rubber or other very fragile parts. I usually don't soak for more than 48 hours and always set out to do the cleaning right after I take it out of the cleaning bath, don't let it dry/reharden. Then a good rinse, H-E-double hockey sticks honestly in tap water but then I let it dry out completely or dry it off with a non-linting rag if I'm going to put it right back in service.

Typically even just a few hours soak will do 6-8 unless it's really bad but I'll use warm or hot water to mix up the cleaning mixture and throw an old power head in there to circulate the bath. All my stuff to soak goes in an old 7 gallon bucket that some salt mixture came in, with like a 15 year old maxi-jet power head

-

Soak it in the vinegar bath before taking it apart. Otherwise you risk breaking stuff you know should come apart but are jammed/fused because of build up. Also pro tip: youll definitely want to pop the volute off that pump and clean the inside of the volute and impeller area BUT 1. Even the very highest quality of pumps unless theyre dissabled and cleaned every few months end up with a stuck on volute that a pain to get off (a second bath of warm vinegar mix can help) which leads to 2. When you finally pop that volute off you might accidentally pop the impeller and or impeller shaft with it. Some pumps use a ceramic impeller shaft which is EXTREMELY fragile and annoyingly expensive to replace. The ceramic magnet of the impeller can be fairly fragile as well so dont hit it on anything. Lastly when cleaning the pump parts dont use a lot of pressure as the impeller teeth tend to get brittle over time and will snap off (also annoying expensive to clean).

If you dont already own one you NEED one of these https://www.google.com/shopping/product/1?q=double+ended+dog+toothbrush&client=ms-android-verizon&bih=766&biw=412&hl=en&tbs=vw:l,ss:44&prds=num:1,of:1,epd:9868948003388706543,paur:ClkAsKraX1kxSWLi_4TrE3tb_ZRAx-lLTURrSblCH-oUYo85Fl8wmnRlq5XSKBAeF-Pl7EhBMCduScXKQ6GWJBNaUpF5u0hZ2kZufB9LhFIGiV3vfyY2do5VExIZAFPVH73M55V3HbcsPFFowgmi5sWhTv-g3w,prmr:1,pid:9868948003388706543,cs:1

Any brand will do as long as its double ended with stiff bristles and one small head and one large head. I use mine at least once a month an 100% of the time when i service my pumps, skimmers, power heads, reactors, H-E-double hockey sticks i even used it to get salt creep out of my radion fan blades.

-

@Still_human have you gotten anywhere on this yet? I feel like someone waiting for the next episode of a show to come out.

-

1. Will the Ice Cap battery back ups run the 300 series pumps?

2. Can you have a battery backup only back up 1 of a pair of gyres? Id rather have 1 gyre run at 30% for 30+ hours than have two run for a much shorter period. -

Id help you out in person but i dont live in MD any more.

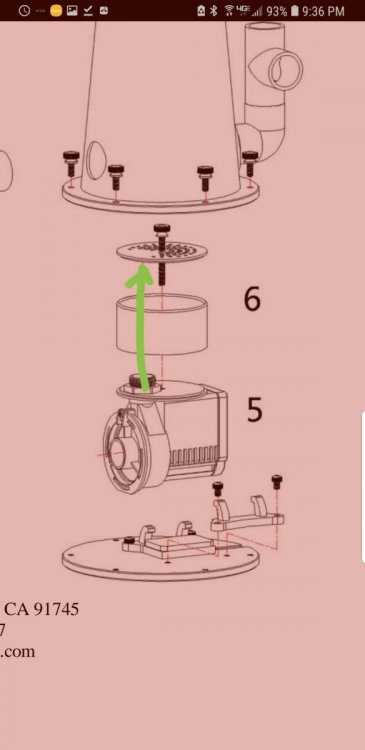

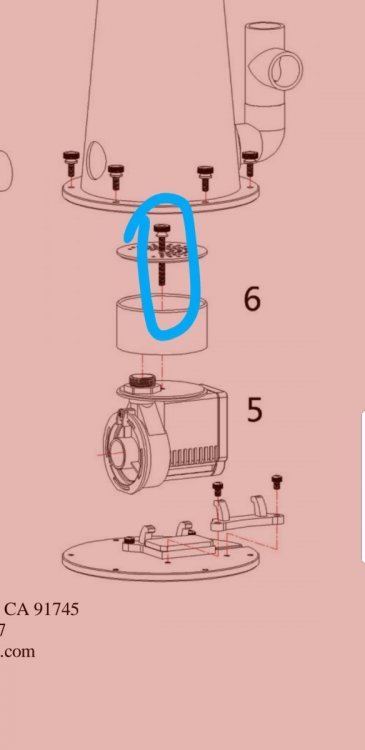

I think you might have an eshopps s120 or s150 on your hands maybe a bit of an older modle but not a bad little skimmer especially for the price of free. It looks like the s150 and larger modles had the bubble plate held on with a nylon screw. I cant really tell on the 120 but heres the manual.

http://www.eshopps.com/manual/snow-skimmer_web-manual.pdf

If is indeed an eshopps skimmer figure out which one and ask them what kind of screw you need and if they can describe to you the orientation of the bubble plate or better yet provide a diagram or picture.

When your vinegar soaking try and pull it apart and scrub with a tooth brush after a 24 hour soak paying special attention to the volute and pump. Build up in there will really decrease your bubble production.

Good luck, hope you get it figured out.

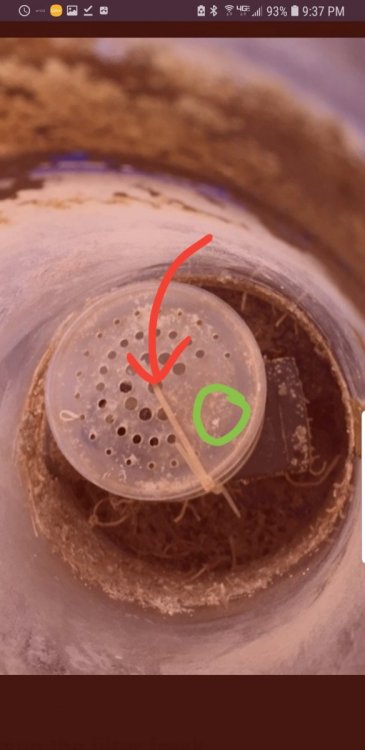

Here you go

Circled in blue is the nylon screw that holds the bubble plate, onto the bubble chamber, onto the pump plate.

Unless they stripped out the threads they probably just lost the screw in which case you can order another one from eshopps (if it is one of their skimmers) or they can tell you what screw you need and you can order the nylon screw from some one else. The part that has no holes in the diffuser plate needs to be lined up so that the outlet of the pump is lined up with it. (See my markings in green) last thing with the red arrow is just showing you where the screw would go in on the picture you took.

BE CAREFUL DISSASEMBLING FOR CLEANING. I would take is as much a part as you can so you can hit every little nook and cranny with a tooth brush right after you pull it from the vinegar soak (also seeing how much calcium build up there us there you might want to use st least 50/50 vinegar to water). But a skimmer thats been treated the way that one has is likely to be brittle in places and your powe cord is going to be super stiff. DO NOT try to unbend the powercord just leave it stiff trying to unbend it may crack the insulation and ruin the pump.

P

-

Actually i think you might have an eshopps s120 or s150 on your hands maybe a bit of an older modle but not a bad little skimmer especially for the price of free. It looks like the s150 and larger modles had the bubble plate held on with a nylon screw. I cant really tell on the 120 but heres the manual.

http://www.eshopps.com/manual/snow-skimmer_web-manual.pdf

If is indeed an eshopps skimmer figure out which one and ask them what kind of screw you need and if they can describe to you the orientation of the bubble plate or better yet provide a diagram or picture.

When your vinegar soaking try and pull it apart and scrub with a tooth brush after a 24 hour soak paying special attention to the volute and pump. Build up in there will really decrease your bubble production.

Good luck, hope you get it figured out.

-

Took a closer look at the first pic. The baseplate definitely comes off. Theres black nylon screws hold it on. Popping that off should give you access to the inside and after you get all that build up soaked off you can prep the surface with some sand paper, a bit of alcohol, and that craftics glue and you can fix that bubble plate back on. Not sure why a zip tie was ever employed.

Its real important you get the diffuser plate glued back on with the holes on the correct side of the chamber.

-

What your looking at is a bubble diffuser plate. That skimmer is so built up with stuff it 100% needs a vinegar bath as all that stuff will inhibit bubble build up.

The zip tie is a jerry rigged solution to a missing screw or broken weld ("acrylic glue"). Some companies attach the plates with nylon screws or sometimes theyre "glued" in place. For example my avast marine skimmer was glued/welded my bubble magnus one is held with nylon screws.

Anyway soak the whole thing in a water/vinegar solution so you can ses what your working with. Post a pic of the underside/buttom of the skimmer.

It would be nice if the base plate came off, im willing to bet it does since the pump is inside.

If you end up needing to glue it (its actually welding technically, this is what you need.

https://www.avastmarine.com/products/craftics-33-1-5oz

-

2 hours ago, Still_human said:

Does this come with an internal pump, so it doesn't need any additional pieces besides the skimmer???

It looks like the pump is in there? Second what @smh254 said. You need to give it a nice 24hr soak in some white vinegar/water like 1:3 ratio.

Regarding something being bent vs broken. I would say the likely hood of anything in our hobby ending up bent is very low due to the materials used most frequently (glass, abs, PVC, acrylic) most stuff straight up breaks

-

Which ones

-

What part is broken? Youll need a cup lid in addition to whatever is broken "inside"

-

-

3 hours ago, zygote2k said:

Looking at your pic, I see that you’ve used the expensive valves used in commercial applications.

BRS sell grey economy gate valves far cheaper than those.

ball valves should never be used near a bulkhead as it will generate torque that can loosen a water tight seal.

The ball valves I used are from supply house, cheaper than BRS and of equal or higher quality. The gate valve is from BRS its the "higher quality" one that can be pulled apart to service.

I have moved all valves away from bulkheads. Which actually resulted in one inside my overflow ?

Need recommendations: Ro/Di storage

in General Discussion

A month ago