-

Posts

10,430 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Store

Everything posted by jason the filter freak

-

It's been 7+ years. What did I miss?

jason the filter freak replied to jason the filter freak's topic in General Discussion

Dead around here 😶 -

LED - 18 years comes offline

jason the filter freak replied to rioreef's topic in General Discussion

Definitely did -

I'm finally back in the DMV* after 7+ years. (Currently tankless ) What did I miss? What's worth seeing? Who had the best bourbon and tank tours? *Rockville

-

Looking to see if anyone can recommend a glassier in the DMV who can replace a panel of Starfire and or eurobrace an existing tank.

-

Anyone here have experience getting a big tank shipped interstate? I just got an offer on a waterbox 7225 that I absolutely cannot turn down in my right mind. I won't be back on the mainland for about 6 months and I want to get the tank shipped from Florida to Maryland. But I have nooo idea where to start at figuring out freight. They'd have to pack the tank, stand, sump, and door to door ship. Any guidance whatsoever would be so appreciated.

-

From the album: Test

-

Avast Marine Works with the mechanical float valve back up. I have 3 of their ATOs including one that been running for something like 10 years.

-

Once upon a time there was a limited run of Avast gear, hats at least. I'm hoping to petition/bully Avast to bring back hats and maybe Tees or something with the pirate flag Avast logo. Tell me you wouldn't rather wear an Avast snap back or Tee rather than a BRS hat, R2R beanie, instant ocean Tee. Or at least add some Avast swag to your reef nerd wardrobe. * Comment if you think they should bring back Avast swag. *Please excuse the appearance of the Photoshop skills of a 5 year old. I infact have the Photoshop skills of a 5 year old.

-

Am I doing it wrong? PAR readings?

jason the filter freak replied to jason the filter freak's topic in General Discussion

I would have assumed pumps on would have lead to artificially low numbers. But I am planning on rechecking today. Both my old lighting scheme and my new one. -

Am I doing it wrong? PAR readings?

jason the filter freak replied to jason the filter freak's topic in General Discussion

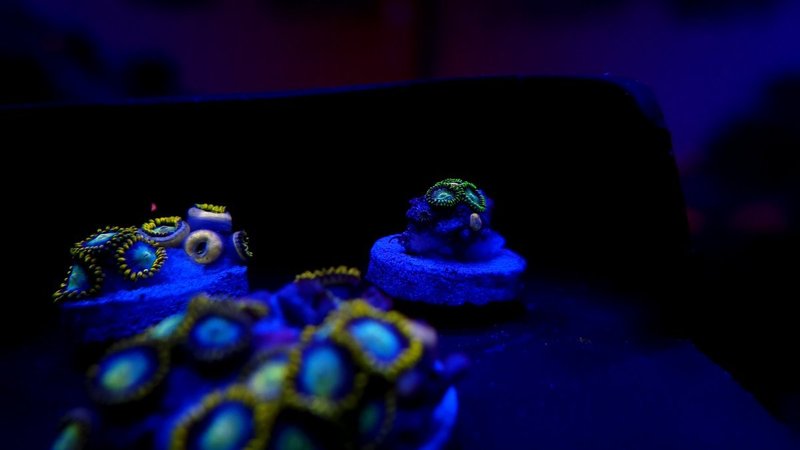

No they're not particularly happy at least some of them it's a zoa/paly only tank so ideal PAR is more like 50-200 average depending on who you believe. I've been having "unexplained" shrinking and melting, that I now assume may be linked to baking my polyps. I'm cutting my light intensity way back. Extending photo period a bit longer, closer to 10, than the 8 I was running and hoping for improvement. I did have an incident or two recently with my tank becoming "too clean". I.e. nitrates undetected by chemical and photo tests and phosphates being sub optimal as well. So I thought that was my issue. -

I think I'm doing it wrong? Using an Apogee MQ510 in perfect condition as far as I know. Also is there a template or program out there to grid your tank in 3D to record readings on? I'm testing my lights Radion XR30pro G4 WITH Radion diffusers on RMS mounts (about 7" above tank+ 2.5" rim to waterline) and about a 10-15 degree tilt toward the back of the tank due to the weight of the XR30 or "design" of the RMS I've attached a diagram of the lighting and tank. Sand bed is black and about 2" deep. Tank is 24" x 32" x 24" LxWxD. Lights are about 3" from each left and right edges and about 4.5" back from front edge. Also attached is the lighting scheme. I was running the preloaded radiant color scheme at 59%. Anyway took some measurements figured I was doing it wrong and gave up. Dead center in my tank left to right, top to bottom, front to back I got ~315 PAR (took the measurements at 57% not full 59%) and all the way down on the sand bed approx 1" from the glass and approx 7" I was getting ~330 PAR. Also of note I'm just remembering I had forgotten to shut off my pumps. So I'm guessing the par may be higher and I can't recall if I scraped the glass first. I realize 2 x XR30PRO are big for this tank but I was truely caught off guard by the readings. Is it possible I'm getting it right before I go though and do a ton of readings? (With the pump off) And adjust my lights to desired PAR 70-150 or so. TIA

-

ID for Zoa? So far no one knows anywhere

jason the filter freak posted a topic in General Discussion

-

Vinegar in Tank. A lot.

jason the filter freak replied to Emhriverdale's topic in General Discussion

@Emhriverdale I've been ER/ICU/Trauma for 12ish years. I was thinking you just meant pouring a whole bottle of vinegar in a tank or maybe meant the air stones part and the only parallel was balancing blood gasses at least that's what I came up with later. -

Vinegar in Tank. A lot.

jason the filter freak replied to Emhriverdale's topic in General Discussion

@Emhriverdale First, glad you saved it. Congrats! Second, I am absolutely racking my brain, how does this bring back memories of the ICU? -

No I don't me green as in covered in algae. I'm interested in all the employed, or reasonable to pull off methods, of reduce, reuse, recycle as it relates to our hobby? I'll start: RODI waste- water a garden/plants bonus if you have a rain barrel you can also fill a watering can if you have indoor plants, fill ponds or pools, vehicle or gear rinse, doggy bath, fill toilet tanks, fill washing machines. Fleece rollers/filter floss- stop using it. Filter socks are so easy to employ and pretty darn easy to wash. Ideally you'd route your washer discharge though a filter sock on a utility since to catch micro plastics out puts. Water change water- If you're not vacuuming your sand bed AND you're pest free donating to someone who's cycling a tank can be very helpful or people with dirty FOWLR especially at higher volumes. (Don't discharge to the ocean please) also helpful for QT tank water changes if you meet the above criteria. Old glass tanks- QT tanks, sumps, water mixing container, reptile and amphibian tanks, green house tanks, you'd be surprised the amount of people looking for tanks with small cracks for reptiles on craigslist/Facebook marketplace/freecycle Old acrylic tanks- pretty much everything above plus cut down the large panes for scrap later fotlr misc projects like frag racks, sump baffles, skimmer stands etc. Old carbon- depending on what you use in your tank chemical wise you can add it to compost and use for soil fill. Old non-led lights- recycle at the very least, they can also be used in other applications for signage or lighting where par/color shift doesn't matter much. Old and or partially burnt out LEDs- fish room or under stand lighting, give them away to your local or non-local DIYer (many people would be willing to pay shipping for your not overly damaged LEDS as they can often be scavenged for parts PVC and hose cast offs from your plumbing- great for QT tanks (I strongly suggest painting a dark color with Krylon fusion or something as white isn't ideal for fish), also keep those 3"+ scraps I can't tell you how many times I've needed to shorten or just slightly lenghten plumbing projects. Old tank sand- Use for ground fill, driveway traction in the winter, or give away there are some people willing to put the work in to wash the sand for reuse. Old tank rock- rinse, cure, and reuse, give away to someone who will rinse, cure, and reuse, can be used by someone with FOWLR or cichlid tanks if you used copper or something on them. Aptasia- check and see if someone is breeding aptasia eating Nudi or training a file fish before drying out those unrecoverable chunks of live rock Asterina stars- if you're scraping them off in large quantities, first sorry, second see if someone local has harlequin shrimp. Macro algae- if you're harvesting cheato or whatever else see if you can give it away to someone starting up a fuge also it can be composted RODI filtration- Look for rechargable resin or refillable resin cartridges Frag plugs- once you've cut your coral off let them dry off to kill any potential pests then toss um in your sump. They'll be cured next time you need to frag something. Live rock rubble from aquascaping- same thing toss the rubble in your sump or unused back chamber, it makes great bio filtration. they also make awesome looking frag "plugs" that blend into aquascaping, If you have a pest free tank consider donating to someone starting up a tank. Can also be used for "pod piles". Shells from dead snails or hermits.- if there's no biomatter in them but you find them unsightly on your sand bed drop them back behind your live rock. Hermits will kill snails for their shells if they can't find readily available shells once they've outgrown theirs Frag cups and fish bags- rinse these and keep them in the back of your fish closet. So much plastic that doesn't need to go to waste. Use them next time you sell corals. Putting those cups inside a bag is a great way to prevent leaks in the event the frag cup starts leaking. If you're accumulating large amounts of cups you're not using. See if your local fraggers want them before resorting to tossing them in your recycle bin. Fish shipping containers and packing- keep them or give them away to your local fraggers. If you're gonna move your tank any time soon they're great for transport. Pro-tip: if you find yourself in need of shipping containers try your local fish store, PetSmart, or Petco moat of the time they just throw them out anyway. Super pro-tip: a lot of places get their fish in mylar coated bubble wrap sleeves instead of foam boxes. Cut the two side seams until theyre long sheets of mylar coated bubble wrap give them a rinse/dry them out and use them for reflective heat barriers in your attic. We had a guy come in for every fish shipment we got a PetSmart back in the day. We have him all the mylar coated bubble wrap and he brought in pictures many months later. He has done all his rafters in something like 800 square foot attic. Dead coral skeletons- not the best LR honestly but if you've got large size/quantities give them away on marketplace/craigslist etc. Many jewelry and decor makers love them for projects. I could keep going but I wanna see what others have.