-

Posts

7,103 -

Joined

Content Type

Profiles

Forums

Gallery

Events

Store

Everything posted by monkiboy

-

monkiboy's 450g display + 250g fish room

monkiboy replied to monkiboy's topic in Dedicated Tank (Build) Forum

Made some holes… three for bean drains going from overflow straight down to filtration room in basement and one for conduit to run extensions of vortech drivers and other things that will be mounted on filtration room equipment panel and two more for two returns from UV to sea swirls. -

monkiboy's 450g display + 250g fish room

monkiboy replied to monkiboy's topic in Dedicated Tank (Build) Forum

Get a build thread going and share the process. Just toss some photos up and it’ll help you stay accountable and inspire ideas of your own and in other members. best of luck finishing the scape! -

monkiboy's 450g display + 250g fish room

monkiboy replied to monkiboy's topic in Dedicated Tank (Build) Forum

and..... done! -

monkiboy's 450g display + 250g fish room

monkiboy replied to monkiboy's topic in Dedicated Tank (Build) Forum

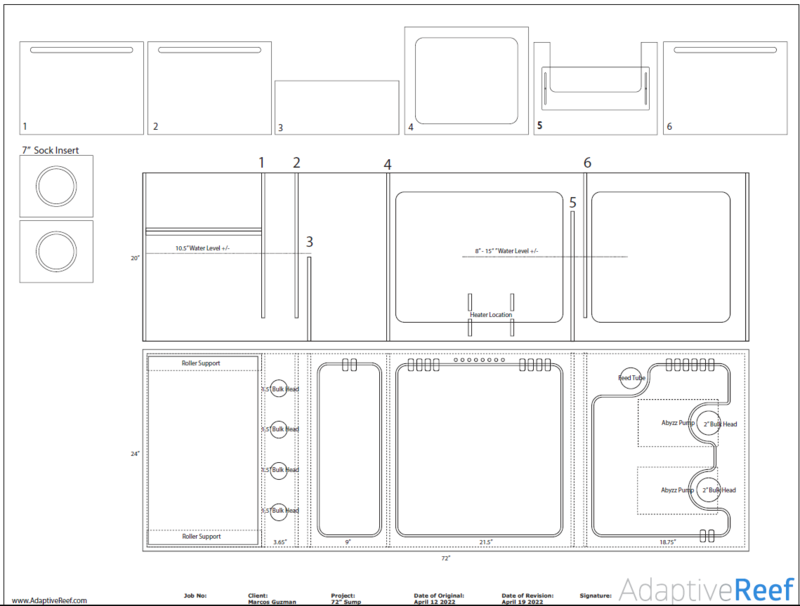

probably a frag rack. not sure. yes, it will have one lid for the section between three and five. currently design shows it as two lids. baffle four is for structural integrity, yes, you are right. good note on potential fuge. definitely concerned about potential to grow chaeto/keep nutrients up even with the large fish load i have planned. between the large skimmer but especially the efficiency of the mrc infinity/rollers in general removing food real time vs letting it break down, i have read and hear the water stay low in nutrients and one needs to add. the skimmer being oversized may have been a big oversight that turns into a co2 reducer, only. we shall see. if i run a fuge for export, i really like the pax bellum line utilizing a reactor to keep things neat and tidy and ultra efficient. thanks for the prompt reply my friend. i really don't like bubbles and adds a bit more rigidity to the build so that's baffle six. answered above about the 9" section between baffle 3 and 4 - rigidity. yes, you got it on skimmer being fed from manifold. the mrc infinity has 4 - 2" intakes one of which will be from skimmer or perhaps that is redundant "cleaning" and it can go to one of the 4 intakes between panel 1 and 2. on bulkheads, yes, some thought will need to be done as I am not sure I will have a ton of room to work with between top of the a400 and the bulkhead. i was thinking of custom bulkheads or just cleanly cutting much of it's length so that the bulkhead tapered/round/finished side could be mounted on top of sump with typical long end below with just enough length to fit a barb fitting and some silicone. i might even need to trim the barb spigot fitting if a400 is too tall. but want to get some silicone tubing if I can find in 2" for isolation. wow, the union. forgot about that off the pump but not a deal breaker with an internal pump. likely will have a true union valve coming off of sump? thought? no room for that above pump but I have to look at specs of pump again. yes, all pump and alignment is coming ready to go from builder based on CAD specs but need to figure out plumbing and where unions and if able to source 2" silicone tubing or just go hard. i will be using 2" flexible pvc all the out to reduce pressure and head in bends, through the UV (all the return water) until the tank upstairs and reduce to 1.5" to the four sea swirls. also very good catch - yes, that's accurate. panel 3 will be reduced, again unlikely to affect me, but IF i do choose I need a lower water level for some reason and just to future proof. yes panel four is structural. right the adjustable baffle is only for future proofing. external skimmer, yes. will only potentially MAYBE need water height to have frag tanks covered but light is fully adjustable so I dont see any issues. i dislike ABS/nylon screws very much so we are using titanium screws everywhere. super smooth and easy operation forever and no gnarled up wet fingers. even on all my reactors i use the slide-loc quick release levers - they are amazing. have you seen them? - https://reefbuilders.com/2022/03/16/slide-loc-quick-release-lever-will-transform-reactor-maintenance/ yes, thank you for the reminder on small volume of water in return section for ATO sensor sensitivity. -

monkiboy's 450g display + 250g fish room

monkiboy replied to monkiboy's topic in Dedicated Tank (Build) Forum

thank you. videos are tough for me and a new form of content creation so I appreciate the support with it. I digest video better and it allows for more understanding for many so I will try to keep it coming. have you posted up a build on here I can check out? Link me and if not, then post up and share the goodness man. We all want to see! -

monkiboy's 450g display + 250g fish room

monkiboy replied to monkiboy's topic in Dedicated Tank (Build) Forum

anyone see anything egregious with the design before I give the "OK" to cut? things to remember/note external skimmer so adjustable water isn't necessary but doing so just in case/future proof left will be mrc infinity roller which takes all flow from tank, to right of that is four more inputs for inputs from frags/fuge/aux, extras, etc. will probably use largest space for reactors or frag rack all panels will be white i requested filter sock holder/inserts just in case i sell sump in future any new owner doesn't want the roller mat/prefers socks probe holder will be separate piece feed tube is for custom avast plank feeder fitted no holes for external pump to avoid creating a hole/failure point all baffles have emergency opening at top in case of some sort of clog under baffle blocking water thank you for any feedback April-19-2022 (1).pdf -

monkiboy's 450g display + 250g fish room

monkiboy replied to monkiboy's topic in Dedicated Tank (Build) Forum

thanks. the UI stuff is a ton of fun and just works so seamlessly and easily vs the cisco/meraki stuff. whole house is wired from cameras, to switches, to APs. this didn't seem like so much as a leap. a lot of stuff in UI early access I am waiting to show up in stock that I really want to play with! the brs gel and instaset work amazing and I was very happy with it. the epoxy I would still recommend for base and critical holds in addition to the gel for extreme angles and the like. mortar I will only ever use again if trying to do something with wet rock. after this experience, I am a huge fanboy for this method to crazy amazing scapes very simply then cycle with structures vs curing rock then building scape. yes, there is a panasonic ERV in the fish tank room and it works amazing well. it's way overkill as it's designed for a much larger space but wanted to give that a go before a solution for the filtration room in basement. another ERV is likely in the cards to keep efficiency up. thanks for reading and providing input alan. long time no see and hope to see more critical feedback as things progress! -

monkiboy's 450g display + 250g fish room

monkiboy replied to monkiboy's topic in Dedicated Tank (Build) Forum

I'm hoping so. I'm especially excited about the abyzz a400 pumps! REALLY hoping I don't have to chuck out for an a1200 to get the flow I want/need upstairs. thank you sir! thank you for following along! to be fair, it's a smaller than normal pallet I think! i'll do an unboxing video for all to enjoy! -

monkiboy's 450g display + 250g fish room

monkiboy replied to monkiboy's topic in Dedicated Tank (Build) Forum

this is all true, haha! -

monkiboy's 450g display + 250g fish room

monkiboy replied to monkiboy's topic in Dedicated Tank (Build) Forum

I'll be sure to do an unboxing video! just posted some aquascape video and photos...still not done, done. -

monkiboy's 450g display + 250g fish room

monkiboy replied to monkiboy's topic in Dedicated Tank (Build) Forum

have a bunch of the other ubiquiti stuff so figured in order to keep the kids safe and keep the fish/reef safe from the kids, more like it, i will need a lock on the door. might as well have some fun with it. currently in video set to a pin but will likely be using the NFC card for quicker access until they allow for a shorter pin code. pretty neat entry and small project with 12v magnetic strike lock and high enough my kids can't reach -

monkiboy's 450g display + 250g fish room

monkiboy replied to monkiboy's topic in Dedicated Tank (Build) Forum

fish room in progress... we dug about six inches below basement flooring and added a floor drain in the process as well. the six inches the room sits in will allow any water leaks or large amount to absolutely stay in the room before trying to make it's way out under the walls. the room can hold about 300g in the floor's six inches as a back up to a back up in case floor drain were clogged for some reason and catastrophic failure of tank (450g) above it. filtration room is a bit small but I am going to have to make it work. 7' x 11' made sure to get a 36" door to allow plenty of clearance for future frag tanks and water storage containers without trouble. basement has a 5' double door entry ten steps away. there is a window in there and obviously then on an exterior wall for any other venting when window will not remain open (extreme temps months) vapor barrier has begun in this photo and other walls as well once plumbing completes. durock on wall shared with furnace room. -

monkiboy's 450g display + 250g fish room

monkiboy replied to monkiboy's topic in Dedicated Tank (Build) Forum

the reef filtration room is under the tank in the basement. directly below. it was used for storage for over a year and this is the mess it was prior to clearing it out for fishy business. -

monkiboy's 450g display + 250g fish room

monkiboy replied to monkiboy's topic in Dedicated Tank (Build) Forum

aquascape almost done... -

monkiboy's 450g display + 250g fish room

monkiboy replied to monkiboy's topic in Dedicated Tank (Build) Forum

the amazing magic of brs gel and instaset... -

monkiboy's 450g display + 250g fish room

monkiboy replied to monkiboy's topic in Dedicated Tank (Build) Forum

some aquascaping work in the freezing cold car port before getting to move the entire operation inside. -

monkiboy's 450g display + 250g fish room

monkiboy replied to monkiboy's topic in Dedicated Tank (Build) Forum

custom modular marine overflow. took two iterations but got it right finally. one thing to note is that they cannot work with sch80 bulkheads like i REALLY wish they could/would for the internal to external box. nonetheless, we will make it work. internal weir box was increased to 30" internal weir uses slots instead of teeth for optimal skimming efficiency and flow through as I will be pushing at least 3500gph height of external box increased to 16" (24x8x16) -

monkiboy's 450g display + 250g fish room

monkiboy replied to monkiboy's topic in Dedicated Tank (Build) Forum

external skimmer and first abyzz a400 pump arrive safely -

monkiboy's 450g display + 250g fish room

monkiboy replied to monkiboy's topic in Dedicated Tank (Build) Forum

built a small catwalk behind tank to make standing and working in tank much easier. this is not complete and will need some redgard and maybe a piano hinge although I don't see needing access much at this moment -

monkiboy's 450g display + 250g fish room

monkiboy replied to monkiboy's topic in Dedicated Tank (Build) Forum

time to aquascape. i used brs gel and instaset which worked amazingly well for some incredible overhangs. then i used epoxy to solidify joints on extreme angles and foundation rock pieces together had my 4-year old helping on this one break rocks apart. used a PVC frame for idea of size and placement in tank -

Yes, sir you do! Come on and join the fun! Let’s get more builds on here!

-

thanks for posting and sharing. we can keep each other accountable with kids and new reef builds!

-

monkiboy's 450g display + 250g fish room

monkiboy replied to monkiboy's topic in Dedicated Tank (Build) Forum

thank you sir! -

monkiboy's 450g display + 250g fish room

monkiboy replied to monkiboy's topic in Dedicated Tank (Build) Forum

Yay! -

monkiboy's 450g display + 250g fish room

monkiboy replied to monkiboy's topic in Dedicated Tank (Build) Forum

Hey Tony! I’m more excited about the process than end result, but it will all be fun and trying I am sure.