-

Posts

4,187 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Store

Posts posted by YBeNormal

-

-

Are you sure that they didn't contain the rare and highly prized translucent coral?

-

Back in the day, when gas was still leaded and a person could still get a good job with a high school diploma or even a GED, Mollies were probably one of the most common ways to cycle a new saltwater tank. Most people only kept them until the tank was cycled, then sent them on a one-way trip to the county water treatment plant though. This was before we understood the value of live rock and that may be the main reason you don't hear about using them for cycling tanks very often. Using them to help control algae though--I'd never even considered that!

-

Ah... I think that setting was disabled when I started my extended hiatus from the forums a while back. Now it makes sense. Thanks for the explanation!

-

I'm not sure I understand the issue here. The storage space limit is for pictures in your gallery. The pictures in your posts are actually just links to your gallery or to an external server such as PhotoBucket. Deleting the links from your posts will only save a few bytes of space.

-

Smaller stands, up to 150G if you do it right, can be safely built with no internal frame at all. For example, here is a project that took 2 days to build for a 75G stand. It's nothing but 3/4" pine panels.

-

Home Depot and Lowes will cut the boards for you, but these will not be precision cuts. Do you have a kind neighbor who will let you use a miter saw? One thing you do not want is a stand with a twist in it or that is not level and square. All calculations regarding load bearing capacity are out the window in those cases!

You mentioned you've never "done this before". Were you referring to stand building or woodworking in general? If you are not experienced with woodworking, building a 150G stand without an experienced assistant might not be the best idea.

-

I have played with structural calculations on this a great deal (I like math and this problem interests me). I have posted this document before, but here is a spreadsheet I put together to run calcs on the span.

Nice spreadsheet. I'm going to have to squirrel that away for future use.

-

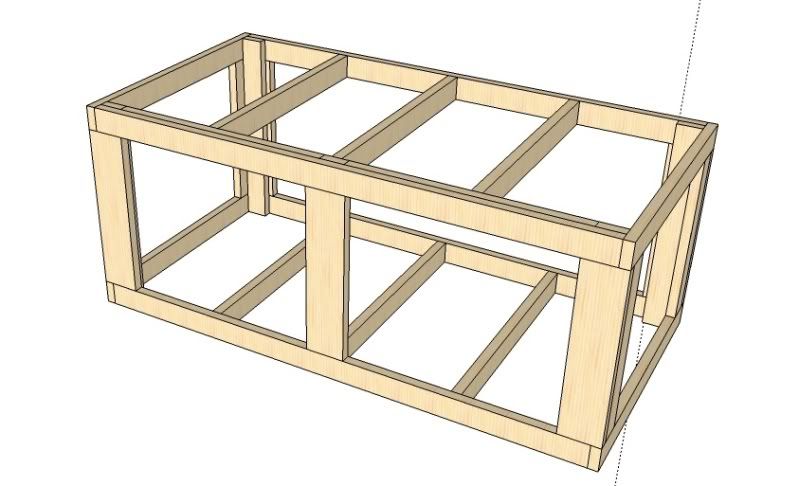

The doubled-up 2x4 depicted on the top/front is not required. A single 2x4 is sufficient.

-

Look in Roni's 300G build thread for a drawing of the frame that I used on his 270G tank. To be very honest, most of the home-built stands are *way* *WAY* (yes I meant to type that twice) overbuilt and the one I built for Roni is no exception. In fact, a 150G stand could be safely built with plywood sides and back and hardwood facing and no internal frame at all! (If you know what you are doing and your joints are well constructed...)

Other than straight edges and accurate cuts, the concerns you need to address in your design are load bearing capacity, shearing and twisting. The vertical supports in the stand (whether we are talking about an internal frame or the external face frame/panels) handle all of the weight. Although a single 2x4 stud can support well over 500lbs of weight (assuming no twisting or flexing), I still support corners of stands for very large tanks using two 2x's glued and screwed to form a 90 degree corner, more for stability than for weight bearing capacity. The horizontal supports at the top of the stand provide some support, but most of the weight is actually on the vertical supports in the corners and center of the stand. I usually use single 2x4's for the top horizontal supports unless I am spanning a large area with no vertical supports in the center.

Once you add hardwood or plywood facing to the frame, and I usually attach that with a combination of wood glue and screws, the stand will not be able to twist or lean, making it even stronger.

-

Maybe Johnny is now Jane?

-

Thanks guys, but the design was Roni's and that's where the credit belongs. All I did was to take his idea and add some wood to it!

-

Steve,

Use the advanced search option. Search by the person's screen name and restrict the search to the dedicated tank section.

Here is the build thread for Gatortailale: www.wamas.org/forums/topic/6245-my-new-215-oceanic/

-

http://www.reefkeeping.ca/forum/showthread.php?3-Aquarium-Tank-Sizes-and-Dimensions

And I found several other links all saying the same thing, 265 Perfecto tanks are not tempered.

-

One year of WAMAS propagation and sharing and they will be going for $10/polyp!

-

http://www.reefkeeping.com/issues/2002-05/rs/index.php

"If you can catch the fish, the isopod may be removed with a pair of forceps. Carefully!!! Upon removal, the fish should be isolated in a hospital tank, and treated with antibiotics until the wound heals. The bug may be disposed of. Carefully!!! About 15 years ago, I had a student who was holding in her clenched hand a 1.5 inch long Aegid. The bug cut through the flesh of her palm, dug in, and started to eat HER. Her vocal response was rather impressive. So was the tenacity of the isopod, it was HARD to remove!"

-

Oh wait, I didn't realize this was Steve's post!

Don't worry about it Steve. It takes at least two months before the wood gets moldy or begins to rot. You have nothing to worry about!

-

I would not worry about the wood rotting or becoming moldy unless the floor is damp. If your concerned about it, you could add a piece of composit decking lumber under the stand or a type of wood that resists mold and decay such as cedar or ipe. Another option is to paint the cement under the stand with a sealer or paint designed to seal basement and garage floors. There are lots of options other than bringing PT lumber into your living areas.

-

We can hook up anytime I also love a good IPA draft!!

That's the second thing we have in common. Let's go for three. Tell me you have a bass boat and know of a great fishing hole in the area!

-

Woodworking is a big thing for me, I get into it way to much.

Welcome Michael! We'll have to hook up sometime and talk woodworking. That's my main hobby and I'm even considering purchasing a laser engraving/cutting system. I just need to do some more research and make sure She Who Must Be Obeyed doesn't get too upset when she sees the $16K-$20k price tag.

-

I think if the meeting (public school) has to close we should convene at another public place like.... say.... HOOTERS.

Should we meet at your usual table?

-

This is really cool. I could see this as the center of a reef room.

-

I did a tank drilling demo at a WAMAS frag fest a few years ago, followed by several members getting to drill a hole or two by themselves. Everyone agreed that it was very simple to do. Just make sure the glass is not tempered, then go for it!

-

Is it really as easy as the videos make it look?

Yes

-

...my tank is no where near that nice.

...yet...

MACNA 2015 in DC!

in General Discussion

Purchased my ticket and looking forward to the conference! As always, let me know how I can help.