Buckeye Field Supply

-

Posts

47 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Store

Posts posted by Buckeye Field Supply

-

-

I have a similar setup and found one issue. With the RO/DI storage tank, make sure that it is closed lid to minimize evaporation. Otherwise, the RO/DI filter is constantly making up for the evaporated water. When this happens the RO/DI filter is not operating at full flow rate / pressure and so the seals in the RO filter may not seal up well. This can result in the DI resin getting depleted faster than it should as it is now cleaning water that has not gone though the RO unit but has instead slipped around it. One way around the problem is to place a ball valve just upstream of the float valve. Then some time after your float valve has cut flow to the storage tank, close the ball valve so that if some water evaporates out of the storage tank, the RO.DI system does not try to keep filling that little bit.

Good Luck,

Bruce

-

Some suggestions:

Unless you need the faster production - drop down to a 75 gpd membrane. It has an 8% higher rejection rate.

You need another check valve. This one goes between the RO permeate port and the ASOV.

You never want a horizontal DI - orient it vertically and pack it very tightly. Bottom up flow is best on these little DI's.

REplace the GAC cartridge with another block. Standard GAC has no place in a system like this. A 10 GPD drinking water system maybe, but not here.

Are you on city water? Do you have chloramines?

Russ

-

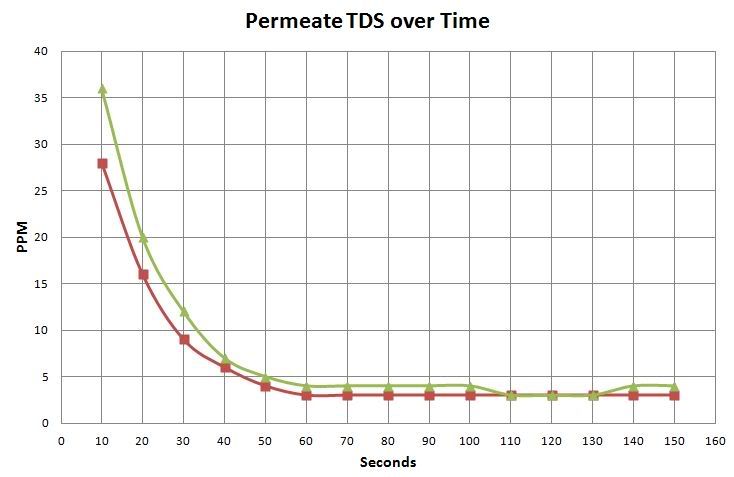

After reading this post I decided to watch my TDS going into the resin when I first turned on the RO/DI today after a week of vacation. It hovered around 70-80 going into the resin for a while and then settled down to about 3-4. Still 0 out of the resin. I wonder if it would help the resin last a little longer if I could put in a little Tee with a valve to drain off that first minute or two of stuff that has been sitting in the filter. Or maybe the volume is enough that it just doesn't matter.

Here's some data from two bench tests with a 75 gpd Filmtec membrane. That initial burst of high TDS water is common to all RO membranes - caused by a process called "TDS Creep."

-

Hopefully you installed your booster pump AFTER your three prefilters.

Again, you have no need for two carbon blocks - I'd pull out the 0.6 block and set it aside. You'll be able to use it some other time. Its reduces the pressure reaching the membrane by a few psi.

Unless you get a guarneteed higher rejection membrane, at 96% your are within spec.

To determine the flow restrictor that is correct for your system, with your water pressure and your water temperature, you have to MEASURE (don't estimate) your waste water to purified water ratio. How?

Line up 7 identical cups (plastic beer cups are perfect for this) in front of your system and turn your system on and let it run for a minute or two. With your waste water tube in one hand, and your purified water tube in the other hand, how many glasses do you fill with waste water in the time it takes you to fill one with purified?

At your pressure with a 75 gpd membrane you are probalbe going to below the target 4:1 ratio. Because at 85 psi and 60 degrees, a 75 gpd membrane will produce 98 gpd. So you'd expect a 100 gpd flow restrictor to give you about a 4:1 ratio. Your current flow restrictor is for a 50 gpd membrane (or for a 75 gpd membrane with cold water and poor pressure).

Russ

-

If you are having trouble getting the housings on and off, my guess is that you have never lubricated the housing orings. You should be using a food-grade silicone grease to lube them each time you change your filters.

Tighten the housings by hand, and may just an 1/8 of a turn with the wrench if necessary. If they still leak then you need new orings. If the orings are lubed the housings will be easy to remove. Don't forget to relieve the pressure in the system before you try to remove housings.

Russ

-

Tink - about half of the time people contat us with odd TDS readings, the problem ends up being bad measurements, rather than actual problems with system performance. What are you taking your water samples in? Are you sure you've let your system run long enough to get past the TDS creep period before you took your sample?

Be advised that ebay is loaded with counterfit products - we see it all the time - so you might want to take an extra minute to make sure you actually bought the membrane you thought you did.

The TW1812-75 has afactory spec of 96 to 98% rejection. The rejection (and the recovery, and the production) should improve a bit over the first 6 to 24 hours of run time.

If membranes are shipped to you dry, rinse if for 10 minutes before use. If shipped to you wet, rinse it for an hour or as specified on the packaging.

Why are you using two carbon blocks on non-chlorinated water?

Why with a booster pump are you only at 55 psi? Is this a non-adjustable off-brand pump?

Do you have any other information of the quality of your feedwater?

Are you certain your RO membrane is fully seated (fully pushed in)?

Russ

-

A good rule of thumb is to replace your sediment filter and carbon block after six months. A more precise way to maximize the usable life of these two (or more) filters is to use a pressure gauge to identify when pressure reaching the membrane starts to decline. This is your indication one or both of the filters is beginning to clog.

Also be cognizant of the chlorine capacity of the carbon block. A good 0.5 micron carbon block for example will remove 9much of the chlorine from 20,000 gallons of tap water presented at 1 gpm. Some original equipment suppliers commonly provide carbon cartridges rated at 2,000 to 6,000 gallons. Remember that all the water you process, both waste water and purified water, go through the carbon block.

Regarding your RO membrane and DI resin, use your total dissolved solids (TDS) meter to measure, record, and track the TDS (expressed in parts per million [ppm]) in three places: 1) tap water, 2) after the RO but before the DI, and 3) after the DI.

The TDS in your tap water will likely range from about 50 ppm to upwards of 1000 ppm. Common readings are 100 to 400 ppm. So for sake of discussion, let's say your tap water reads 400 ppm. That means that for every million parts of water, you have 400 parts of dissolved solids. How do we go about getting that TDS reading down to somewhere near zero?

If you do some experimenting with your TDS meter, you'll note that your sediment filter and carbon block (collectively called “prefilters” because the treat the water before it reaches the membrane) do very little to remove dissolved solids. So with your tap water at 400 ppm, you can measure the water at the “in” port on your RO housing and you'll see it is still approximately 400 ppm.

The RO membrane is really the workhorse of the system. It removes most of the TDS, some membranes to a greater extent than others. For instance, 100 gpd Filmtec membranes have a rejection rate of 90% (i.e., they reject 90% of the dissolved solids in the feed water). So the purified water coming from your 100 gpd membrane would be about 40 ppm (a 90% reduction). Filmtec 75 gpd (and below) membranes produce purified water (a.k.a. “permeate”) more slowly, but have a higher rejection rate (96 to 98%). The lifespan of a RO membrane is dependent upon how much water you run through it, and how dirty the water is. Membranes can function well for a year, two years, or more. To test the membrane, measure the TDS in the water coming in to the membrane, and in the purified water (permeate) produced by the membrane. Compare that to the membrane’s advertised rejection rate, and to the same reading you recorded when the membrane was new. Membranes also commonly produce purified water more slowly as their function declines.

After the RO membrane, water will flow to your DI housing. DI resin in good condition will reduce the TDS in the RO water down to 0 or 1 ppm. When the DI output starts creeping up from 0 or 1 ppm, you know that your resin needs to be replaced. Sometimes people complain that their DI resin didn't last very long. Often the culprit is a malfunctioning RO membrane sending the DI resin “dirty” water. This will exhaust the resin quicker than would otherwise have been the case. Sometimes the problem is poor quality resin – remember that all resins are not created equal.

Additionally, don’t forget to sanitize the entire system at least once per year, and wash and lube your housing o-rings with food-grade silicone grease every filter change.

Russ

-

If I were to decide to start again, I would build my own. It should be apparent to you that every company uses the same plastic canisters, the same mounting hardware (basically-but this has no effect on performance) the same plastic water lines, some use slightly better connections, and everything else membranes, filters, tds meters, pressure guages, etc. are all in line products that they themselves add onto the unit.

A RODI unit is seriously the most off the shelf product I have ever seen.

Keep the canisters you have, keep the mounting hardware, if you want to add a membrane, get a clip on holder from BRS. Buy the BEST membranes and filters for your needs, get proper size flow restrictors, buy the best in line TDS (but I second the handheld option for accuracy's sake), buy the best pressure gauge, replace all your current fittings with John Guest fittings, get some new water lines if you think it's necessary, add a solenoid, whatever. You now have a product that is most likely superior to all of your pre assembled options, for probably less money, since you reused some older parts.

We'll repectfully disagree with you on this. There are significant differences in the housings, brackets, pressure gauges, asov's, fittings, configuration, etc. If you've not held many brands side by side the difference wouldn't be obvious.

Russ

-

I put an auxiliary pump to get more pressure but coupled with the COLD water my output is still not at rated capacity so the system runs a lot to make my water.

Something may be wrong with your system. For example, let's assume you've adjusted your pump to 80 psi, and you have very cold tap water at 50 F: With that combination of temperature and pressure, a 75 gpd membrane should produce... 75 gpd. With water a little warmer at 55 F, a 75 gpd membrane should produce 83 gpd.

Depending upon the brand name of your membrane the gpd capacity usually has a plus or minus fundge factor in there - often something like 15%.

Russ

-

is there really a difference in RODI units?

guess im confused on how one could pass water better thru the same filter vs the next?

After building these sytems for over 15 years, I can tell you w/o a doubt, yes, there is a difference. And that difference in not limited to the replaceable filters. I can expand on this if people are interested.

Russ

-

Let's back up a little.

Regardless if we're talking about a 24 gpd, 50, 75, 100, or 150 gpd residential membrane, the manufacturers suggest something near a 4:1 ratio to help assure a reasonable life span on the membrane.

That ratio is set by a small $4 piece called a flow restrictor. If you'd like, you can install a different restrictor and get a different ratio. Will take you all of about 2 minutes.

We feel it's misleading to tell people they can cut down on waste water by adding a second membrane plumbed in series. Here's why.First - remember that what folks call "waste water" really would be better thought of as "flush water" in that this water serves the important purpose of internally flushing the surface of the semipermeable membrane to keep the membrane from fouling/scaling.

When you configure a system with two membranes in series (the waste from the first membrane going to the "in" port on the second membrane), for this discussion let's say it's two 75 gpd membranes, the system behaves like you have a single long (75 gpd x 2) 150 gpd membrane.

Now - if you use a proper flow restrictor, that is, one for a 150 gpd membrane, and have something near the factory spec water pressure and temperature, you'll have about a 4:1 waste to product ratio. Sounds familiar, right?

If however you don't change the flow restrictor - meaning you keep using the same restrictor you were using when you had just one 75 gpd membrane, then you'll see a waste to product ratio much lower than 4:1. But remember that the recommendation for a ~4:1 ratio comes from the membrane manufacturer. They are telling you that you need about a 4:1 ratio to keep the membrane flushed and keep the membrane from fouling or building up scale. Run the system with a lower ratio and you will foul/scale the membrane(s) quicker than would have otherwise been the case.

Instead of adding a second membrane to lower that ratio, you could have just changed out your flow restrictor ($4) instead. This is a much less expensive approach to get you to the same endpoint in terms of saving on waste water.

Now, to confuse things just a bit. Filmtec specs call for the 4 to 1 ratio on the basis of assumptions about the water that will be supplied to the membrane. If you have very soft water you MAY be able to get a decent service life from the membrane running at a ratio lower than 4 to 1 (e.g., 3 to 1). Remember that the waste water from the first membrane is about 25% harder than your tap water.

Bottom line: If what you are after is reduced waste water, experiment with a different flow restrictor for $4 instead of messing around with a second membrane plumbed in series.

As a side note, you can also lower the ratio by increasing the pressure delivered to the membrane (with a booster pump), because flow restrictors are sized assuming you are providing factory spec conditions (50 psi and 77 degrees for Filmtec membranes). Increase the pressure and you'll drive more water through the membrane and viola - less waste water. But as I mentioned above, if you do this (just like over-restricting a membrane) - the lower the waste to product ratio, the shorter the lifespan on the membrane.

Makes sense?

Russ

-

I'd use 1/2" or 3/4" pvc - but you could use whateve size you'd like. Bigger diamer fittings are a bit more expensive.

Use bulkheads - I think this is an application where the expensive bulkheads are not necessary.

I don't see that check valves would be needed.

I wouldn't put fittings on the inside of either bulkhead - you may need an elbow on the lower one to limit splashing.

To go to flex tubing, use a pvc fitting with 1/2" fnpt. Screw into that a 1/2" mnpt x 1/2" quick connect fitting. Plug in a length of 1/2" PE tubing and end it in a 1/2" quic connect ball valve.

What do you mean when you say "flex tubing?" That will affect what sort of valve is appropriate.

Yes - I'd put in a union so you can break everything down to clean it.

Russ

-

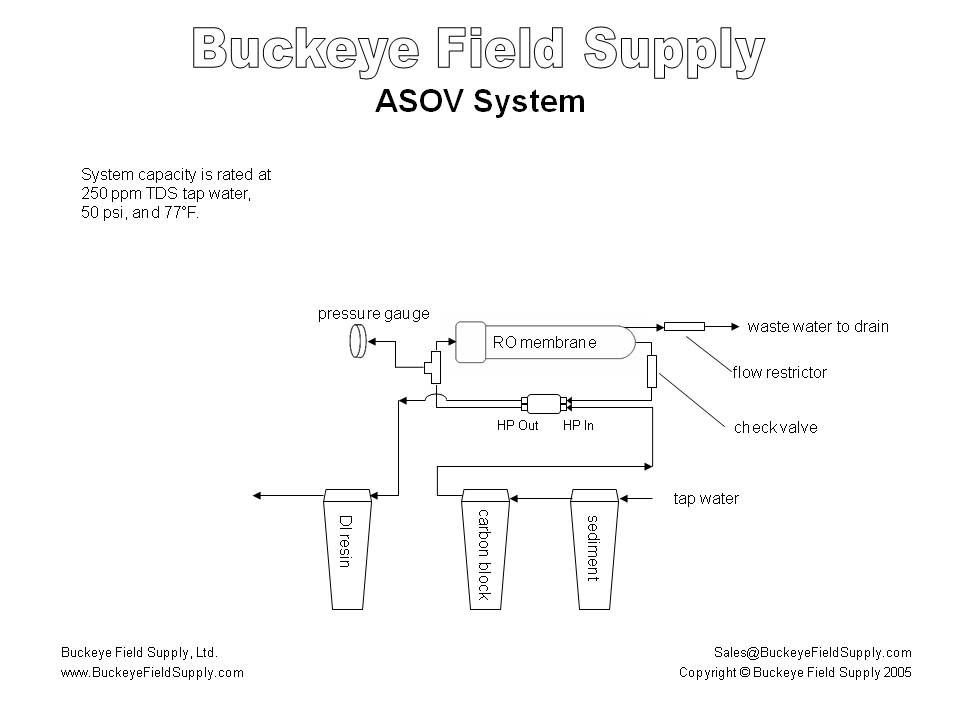

Here's a graphic that should help you check your plumbing:

Also - if you have air trapped in your DI housing go ahead and burp that - it will speed up the action of the ASOV.

Russ

-

Should be about a 4:1 ration.

And yes - I've used waste water from the RODI at my house to fill the washing machine for years.

Russ

-

Before anyone installs one of those self piercing needle valves, might want to take a look at the write up we did on those - on our facebook page.

Russ

-

Also keep an eye on that clear RO membrane housing. Those always seem to develop cracks as well. I don't think even Purelyh20 uses them any more.

-

This looks like the system I have ...

http://www.purelyh2o...&category_id=80

First picture shows the full unit

second one shows the individual filter cartridges

and their order (right to left)

I have zero confidence that this was put together correctly before I got it

The sediment filter is 1 micron

and so is the carbon block

reading the website description is shows the Catalytic third

Do we think that is incorrect?

The RO Membrane says 75 GPD

Everything I read says the 100 gpd units are worthless

and I think 150 would be overkill for me, so I guess I'm staying with this one

Thanks for all the help!

Can't tell from your pictures but does that inline taste and odor filter (above the membrane) come AFTER the DI? If so, remove and discard it - it's doing more harm than good. Yur water is as clean as your system can make it immediately after the DI. You'll add TDS by running DI water through carbon - and you are wasting your money.

Keep a close eye on the male threads on those clear housings. They are prone to crack. This is a good example of why I cringe when I hear people say "all RODI systems are alike." Absoluetly not true. Those housings for instance are very very inexpensive on the wholesale market, but we won't use them.

Russ

-

I know this is an old thread, but I just saw it.

Remember that these hydraulic shut offs like this:

were originally designed for use with drinking water RO systems. These systems have very slow membranes (e.g., 12 gpd) and a pressure tank that provides gradually increasing back pressure on the membrane as the tank fills. In this hobby we use them with much higher-capacity membranes, and float valves the go from 100% open to 100% closed in a heartbeat.

So especially when you need an ASOV to work on a system with a booster pump, instead of the traditional hydraulic shut offs, consider using instead a pressure switch and a shut off solenoid like these:

This provides the added benefit of also shutting off the pump when your reservoir is full.

Russ

-

It has a Sediment Filter

what is the pore size?

a 1 micron Carbon blocka catalytic carbon filter for Chlorimine

the RO membrane

and the DI Resin

The carbon block should be AFTER the Cat GAC

Matt - pull the membrane out and you should see a sticker on it. Should have a code something like "TW-1812-75" Where "75" is the gpd rating.

Russ

-

So, if my in is 800, its OK to supply my aquarium with water of 80 TDS, but if my in is 200, then its only OK to supply my aquarium with water of 20 TDS? That rule doesn't make any sense.

Once you start having a reading, its time to change it. Its not an emergency or anything like that, but its near or at capacity and its time to change it.

This is right on the money.

-

Why is sending water from the storage tank to the DI a bad thing??? I have had my system plumbed this way for years...

Remember that RO membranes function based upon the differencein the pressure on the feedwater side of the membrane versus the pressure onthe storage tank side of the membrane.

So for sake of discussion let

-

I asked the same thing above because I am not sure I understand either... two reasons that I can think of: rust like you mentioned (although I am not sure how much of an issue that is with an RO unit that is generally well away from salt water and anodized or powder coated), and weight... some of these systems can get pretty weighty...

Both of the reasons I thought of, though, don't really directly affect the operation of the unit.

Right - the rusted bracket just ends up looking sort of scabby...

-

I was with you all the way until this one. What's wrong with steel?

It rusts - even if powder coated, the steel brackets will rust over time.

Russ

-

In your specified range the 75 GPD is probably what you want to be looking at, the DOW and filmtec both have ~98% rejection rates.

Just so people don't get confused, FILMTEC is the brand of RO membranes made by DOW.

Russ

.jpg.cec6c540fb2da6431942d5ff09ef7a2d.jpg)

Help with RODI diagram for drinking water & reef tank

in General Discussion

Good advice - avoid short cycling where TDS creep water ends up being a large percentage of the water that ends up in your reservoir.

Russ