-

Posts

434 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Store

Everything posted by tom39

-

Way to silence a skimmer pump? Or kill your tank?

tom39 replied to astroboy's topic in General Discussion

The foam is an insulation and incapacitating the pump in it would trap the heat in the pump by not allowing it to dissipate. This would cause the pump to overheat and prematurely fail. Sent from my SM-G981U using Tapatalk -

I am looking for opinions from anyone who has used one of the Innovative Marine Auqashield UV Sterilizers? What was your thoughts on its effectiveness? What was the lifespan of the bulb? Did it require a lot of maintenance? Was the sponge provided for mechanical filtering easily clogged? Would you purchase it again and would you recommend it to a friend? https://www.innovative-marine.com/product-page/auqashield-11w-uv-sterilizer-clarifier-midsize For reference, the tank that I intend to use the UV filter on is an IM 40g Fusion, it is set up as a frag tank and will only be a home for 2 clown fish. Thank you in advance, Tom

-

Here's a picture of it installed. Its hard to see but if you look closely, you can see how the water still enters the chamber without restriction but does so only on the outside of the chamber. Another benefit is how calm the water level is inside of the chamber. This should allow for a more accurate water level reading. Sent from my SM-G930V using Tapatalk

-

I am in the process of setting up an IM 40g Fusion for a frag tank. One of the issues that I ran into was that my Tunze 3155 ATO would consistently fail and overfill my tank to the point that the overfill float sensor would shut off the pump and set the overfill alarm. After a bit of searching a few different forums and websites I have come to find that my problem was that air bubbles were collecting on or around the the optic eye. With a better understanding for the reason for the failure, I then better understood at least one of the reasons why Tunze makes the 3152 model, which is the ATO without the optic eye. In an IM AIO tank, the only place you can place the sensor for the ATO is the return section, the return section will almost always have bubbles that will collect in the chamber. These bubbles will eventually collect at the eye which will disrupt its ability to determine water level. Anyway, because I just bought 2 Tunze 3155's (1 for use and one for backup) I didn't want to have to buy 2 more 3152's, so I came up with a solution to my issue. I made a bubble diffuser or baffle around my ATO sensors that fits right inside the return chamber and keeps bubbles entering the chamber to float to the top of the water but outside of the diffuser. Thank you for looking, Tom

-

+1 for the use of muriatic acid. When I bought 150g vessel, it was used and was stained brown inside. Muriatic was the only thing that would do the job and do it efficiently. I mixed up 2gal of a 5% solution and then used a stiff brush and a bit of soaking to get it looking like new. Just remember, if you use acid it is best to do the work outside.

-

I love your method and your thought process. OK, so I am currently processing water and this is what I am able to achieve with my system at this moment. If you would not mind, please let me know if my thought process is off. TDS coming in from city water supply is 77 TDS Pressure coming in from the city water supply and feeding the 1st RO filter is 66psi Pressure coming out of the 1st RO and entering the 2nd RO filter is 60psi Product water TDS coming out of the 1st RO filter - 1 TDS ** Product water TDS coming out of the 2nd RO filter - 1 TDS * / ** / *** * Unfortunately I do not have a TDS reading of the water coming from the waste line that is feeding the 2nd RO filter. ** The numbers coming out of the RO this morning I am attributing to the low TDS from the city water source and the fact that my RODI has been making water since 5 pm yesterday and I have flushed the RO membranes 2x since starting the process. Normally the source water is 100-110 tds and I usually get a product water from the RO's of about 2 tds. *** Note that is RO filter is the newest of the 2 and has processed about 1000g less water than the 1st RO filter So with the RO's reducing the TDS from 77tds to 1tds the rejection rate is 98.7%. Both of my filters are DOW filmtec 100gpd RO filters (not sure if they are the high rejection filters), so using the acceptable rejection rate in the spec, technically I would be good to continue to use the filters until I reach a TDS reading at the output of 7.7tds. That is if the input water source remained at the current value 77tds. The spec says that: Filter model: DOW Filmtec TW30-1812-100 TFM100 membrane, TW-30-1812-100HR for High Rejection. Size: 11.75" x 1.8" Flow Rate: 100 gallons per day @ 60 psi water pressure Average NaCl Rejection rate: 90% rejection rate for regular, and 98% for High Rejection. Thank you, Tom

-

I started in the hobby about May of 2013 and that is when I put my current RODI into service. My first tank was a Marineland 50g corner and the evaporation rate was about 1.25g/day. I did regular water changes that were 10g every 2 weeks and I kept that tank for about 4 years before I shut it down and set up my current 150g cube. For that tank I keep roughly the same schedule of water changes but due to its size I have an increase in evaporation of about 1.5 to 2 gal/day. In addition to those 2 tanks, over the years I have had a number of additional tanks and setups, all of which increased my water usage. By my calculations (very rough estimate) I have made about 6,500 gallons of RODI in the past 6.5yrs and I never make less than 50g at a time. Additionally, I always flush my RO filters for about 5-7min at the start of processing a batch of water. Anyway, the point of all of this is that I was wondering how long a RO filter typically lasts. My RODI is a 200g/day setup with a single 5 micron sediment filter, dual 5 micron carbon stages, dual 100gal/day RO filters (piggybacked) and lastly a dual DI stage. My current TDS numbers at the output of the RO's are 1 TDS for the first RO and 2 TDS coming out the second RO, this is with a source input water at about 100-110 TDS average. I believe that the second RO is only this high because this filter is reprocessing the waste water from the first RO filter. With the filters currently making a max of only 2 TDS, at this rate I cannot foresee the replacement of these filters for many years to come. My questions are: What TDS numbers are others getting out of their RO filters? How long has their current RO filter been in service? How often are you replacing your RO filter? What brand of RO filter are you using? How much water do you make at a time? Do you use a flush kit? Thanks in advance Tom

-

Thanks for the compliment. [emoji4] Sent from my SM-G930V using Tapatalk

-

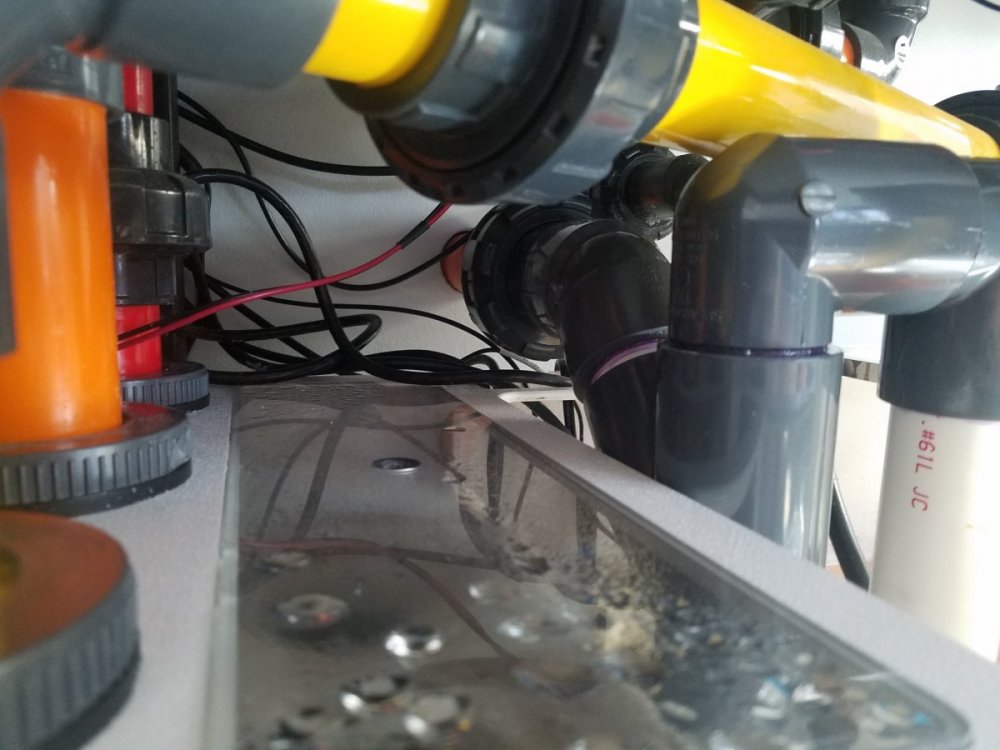

A picture would be helpful but if I understand what you are trying to convey, you are looking to not glue the pipe that enters into the bulkhead fitting (outside of the sump) that is affixed to the sump. I've attached a pic of my sump plumbing for reference of what I have done. The orange line (center) is the full siphon, the yellow (front) is the backup and the red (back) is the emergency line. Where the plumbing enters the sump at the bulkhead fitting, is that the joint that you don't want to cement? IMO, as long as the pipe is after the valve you should not have an issue with sucking air or making noise. My guess is that you will end up having ongoing salt creep at the joint that is not glued. In my setup, if you look at the picture, I placed the unions further up the line from the bulkhead due to close spacing of the holes. This way the pipe can still be removed by loosening the upstream union and then unscrewing the bulkhead nut on the otherside of the bulkhead. Once undone, it allows me to then lift and remove the whole section of plumbing from the valve to the sump. Sent from my SM-G930V using Tapatalk

-

How far under the surface of the water is the hole? Without seeing the issue, a guess at a solution would be to place a small hood over the spout that would diffuse the water spout before it made it to the surface. A picture of what you are seeing and what is happening would be helpful. Tom Sent from my SM-G930V using Tapatalk

-

How do you plan for vacation or time away from home?

tom39 replied to Yachaq's topic in General Discussion

I have always found someone to tank sit for me. Usually a neighbors kid or a college student that is looking for a little spending money. I don't however leave anything to chance or to their discretion. i do this by leaving simple but detailed instruction, have a controller installed on my tank and I also put the following in place to insure there is not a mishap. 1. My ATO has a 10g tank that gets auto filled 2x a week via a storage tank in my garage. This way, no more than 10g of fresh water can be introduced into the tank at any time 2. The lights are automatic but can be controlled remotely if the need arises. 3. The skimmer has collection vessel that also has a float that will shut the skimmer down if it overflows.If this occurs, I get an alert from my controller informing me of a potential issue. 4. I replace the filter socks prior to leaving and make sure the feeding is light while I am gone so the chances of them clogging is low. 5. I pre-package frozen food in 4oz specimen cups and keep them in the freezer. The instructions are that the fish get fed 1x a day while the lights are on and all they have to do is pour some water in the cup, wait for the food to melt and then pour the food in the tank. 6. I leave Nori and Veggie chips near the tank and the rule is that they can attach either one to one or both of the chip clips in the tank anytime they want. I currently feed this treat 2-3x a day so I am not afraid that there would be an issue with feeding too much. Plus, I don't leave an unlimited supply. 7. I pay them well. I find that if I do this, they feel accountable and will take the job seriously. 8. Place a wifi or web cam focused on your tank to monitor your tank and room (tell them that you have done this or you will send a message that you don't trust them or are just a weirdo creeper). Some of the new cameras available are super easy to set up and I even got one that I set mine up so that it senses motion and I get an alert to notify me that there is movement in the room. I can then watch that they have fed the fish or have a visual if they have an issue that I might be able to solve by having the visual. That's about it. I make it easy and I have never had an issue. -

^^^ This is the best advice. Additionally, some things to remember is that drywall is not structural and a raw edge of drywall will degrade very quickly when an object rubs against it or water is introduced to it. When I ran my plumbing through the wall, I reinforced the opening by using a piece of plywood and/or sheet pvc affixed to the wall where the pipe entered or exited. (The pic is where I reinforced the conduit exiting the wall with a piece of pvc sheet material. It has definitely helped insure that my drywall is protected. Also, in an effort to make sure the piece held in place and the screws did not pull out, I inserted drywall anchors into the drywall prior to adding screws.) As for making holes, dpassar12 suggested as I had done and used a hole saw to drill the holes in the drywall. Just remember that drilling through the drywall is not a race and the slower you go the better the chance that you will get a clean hole without any blowout when you punch through the other side.

-

That is a really big skimmer and without a doubt a beast! But I am not sure that your system would even come close to having enough bio-load for the skimmer to be effective with what you stated you have planned. A quick search has indicated that the XP-8000ext is rated for a 800 gallon heavy bio-load system up to 1200 gallon if the bio-load is light. That's almost 3X the total water volume you have indicated for your planned (both tanks combined) system. I hate to say it but my suggestion would be to consider other options and forgo the use of the skimmer.

-

IME, for the most part you can, its only when you are trying to piggyback an RO membrane that the GPD value must match. Sent from my SM-G930V using Tapatalk

-

You will not be able to use the BRS 150gpd Water Saver kit as it would require that you have 2 - 75gpd membranes. You could however convert your system to a 180gpd system by adding an additional 90gpd membrane. However, the 90gpd membranes are expensive and not easily sourced and if it was me, I would convert the system to 2 - 100gpd membranes for the same price as 1 - 90gpd membrane. But since you just installed a new 90gpd membrane there would not be of any benefit in cost to convert to anything else. The only items you will need to convert to 180gpd are: (Please note that the links are for representation and reference only) IMO, an insanely over-priced membrane - https://www.amazon.com/Spectrapure-90-GPD-Percent-Rejection-Membrane/dp/B016MN05IU/ref=sr_1_fkmr0_1?keywords=filmtec+ro+membrane+90+gpd&qid=1550106772&s=gateway&sr=8-1-fkmr0 A membrane housing - https://www.amazon.com/FS-TFC-Membrane-Quick-Connect-Fittings-Menbrane/dp/B071DY62J1/ref=sr_1_1_sspa?keywords=filmtec+ro+membrane+housing&qid=1550106848&s=gateway&sr=8-1-spons&psc=1 A set of housing clips - https://www.amazon.com/Reverse-Osmosis-membrane-diameter-membranes/dp/B0185DRO66/ref=sr_1_4?keywords=ro+membrane+housing+clips&qid=1550106894&s=gateway&sr=8-4 A bit of 1/4" RO hose - https://www.amazon.com/PureSec-4TU-WHI-Certified-70°F-120PSI-150°F-60PSI/dp/B01MT559ZE/ref=sr_1_12?keywords=1%2F4"+ro+hose&qid=1550106990&s=gateway&sr=8-12 Hooking the 2 membranes together is simple but IMO you will have to have at least 55-60psi water entering the first membrane if you want the membranes to be efficient - The waste water from the 1st membrane is fed into the inlet of the 2nd membrane. The waste water from the 2nd membrane exits the housing and is directed to through the flow restrictor (NOTE**Only one restrictor is needed**) and is discarded. If you want to use your flush (Highly recommended), only 1 flush valve is needed and should be plumbed so that the flow restrictor is by-passed when the flush valve is opened. The product water from both membranes is collected and is fed through the DI. Hope is helps, Tom

-

Well having just read this thread, I am now curious of how the repair turned out.

-

Buy 2 Vertex ROX Carbon - Get the Somatic UF-1 FREE

tom39 replied to Premium Aquatics's topic in Premium Aquatics

Additionally, the link to be emailed when the item is available is broken and will not allow an email address to be submitted. Sent from my SM-G930V using Tapatalk -

Need suggestions for removing mushrooms from rock

tom39 replied to John-Solo's topic in General Discussion

In one of my previous tanks I was able to control the numbers of mushrooms by injecting the unwanted through the center and into the base with muriatic acid using a syringe I purchased from a pharmacy. In my case, for much of the purge, I pulled the rock, injected the base of the unwanted, then did a quick rinse of the rock before placing the rock back in the tank. Once I got the numbers under control, I simply injected the unwanted while they were still in the tank. Just be very careful with the use of the acid (see warning labels on bottle) and also be mindful that its use may have an affect on your tanks alkalinity and PH. Additionally, the toxins in some mushrooms are very powerful and can cause negative effects to a person if not handled properly. I found this out the hard way and since my mishap, I always wear gloves and eye protection when working with any corals. Sent from my SM-G930V using Tapatalk -

Buy 2 Vertex ROX Carbon - Get the Somatic UF-1 FREE

tom39 replied to Premium Aquatics's topic in Premium Aquatics

Website shows that ROX carbon promotion is on backorder. Any idea of when it will be available? Sent from my SM-G930V using Tapatalk -

Thanks, I am very happy with the results. Not worrying about an overflow problem is certainly a plus. Sent from my SM-G930V using Tapatalk

-

Yes, just a little bit above the surface. With it being above the surface, it allows me to hear that there is an issue with the flow through the valve. Sent from my SM-G930V using Tapatalk

-

How would you glue or bond the seams together? I have used this sheet material for many projects for my tank (Mostly catch pans and stands) but have only screwed and stapled it together as I have not found an adhesive, glue or cement that would bond the material to itself. If you do know of a particular glue, adhesive or cement that will bond the material, please share. Tom

-

My setup utilizes an external skimmer that is housed in a closet to the right of my DT. To feed the skimmer, water is pumped from the sump, which is located under the DT, through 2 walls and to the skimmer. The return takes a similar route and is returned to the sump. The fall in plumbing from the output of the skimmer to the water surface in the sump is about 16" and travels about 36". During the return to the sump, the water picks up a bit of speed and prior to building my defuser caused quite a bit of noise, salt creep, micro-bubbles and splashing. In an effort to reduce all 4 of these negative effects I put together about 5 renditions before settling on this one, which by the way works flawlessly. How it works: The valve at the end of the pipe is the main point of exit. This valve is used to throttle the exit of water to allow only 99% of water pass. This causes the water to climb in height inside the defuser until it reaches the 90* elbows (bypass line) where the remaining 1% of water is allowed to trickle to the water surface of the sump. Because there is so little water going down the bypass line it tends to run down the walls and create only the smallest of streams entering the sump. This effect creates no nose, salt creep, micro-bubbles or splashing. Anyway, I thought that I would share what I have come up with in case anyone who uses an external skimmer has a similar situation and is looking for a solution. Thanks for looking, Tom G It was really hard to get a pick while it was installed but I hope they help with the understanding of how it works.

-

Were you able to hang the light as you intended? If not, did you happen to find the size and pitch of the mounting hole in the light? I have an idea of how to make it work but knowing the size and pitch is a major part.

-

Is there water in the tank? Or is this a new build?